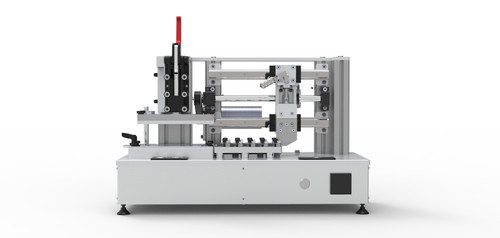

Introducing the ADVANCED WIRE SHOOTER, the next evolution in wire insertion machines for acetate frame production. Designed with versatility and power in mind, this machine offers unparalleled precision and control, supporting a wide range of wire types and frame styles. With exchangeable guides, it allows for easy switching between different side wire widths and the ability to insert wires with or without hinges, including advanced OBE hinge solutions.

The ADVANCED WIRE SHOOTER is built for small-batch production and can handle acetate slabs ranging from 20 mm to 50 mm in width. Its stronger motor, enhanced safety features, and easy adjustments for different acetate thicknesses ensure that this machine delivers optimal results, time after time. Additionally, its ability to insert wire in any desired position—centered or off-center—gives frame makers maximum control over the production process.

Wire Compatibility

- OBE Flat Wire

- OBE Wires with Non-Flex Hinges

- OBE Standard and Premium Flex Hinges on Wires

- Many other wires with or without higes between 3 and 5.1 mm

- Other widths with additional wire guides upon request

How It Works

- Adjust the guides for the required acetate slab width and check the correct brass wire guide is installed.

- Heat the acetate slab in the ADVANCED SIDES HEATER.

- Load the flat wire or hinged wire into the wire guide and lower the pusher.

- Place the preheated acetate in the material bay.

- Secure the material with the toggle clampt and backstop.

- Hold the arrow button to insert the wire while holding the safety button.

- Wait for the material to cool down (about 15 seconds), and you're done!

FEATURES

- Exchangeable guides: Compatible with various side wire widths, including OBE flat wire and wires with hinges.

- Wide material compatibility: Accommodates acetate slabs from 20 mm to 50 mm.

- Precision control: Easily adjustable for centered or off-center wire insertion.

- Strong consturction: Enhanced strength for greater durability and smooth performance.

- Advanced safety features: New workflow and guards to ensure safe operations.

- Quick adjustments: Adaptable for various acetate thicknesses without complex setup.

- Compact design: Optimized for professional results in small workspaces.

TECHNICAL SPECIFICATIONS

- Voltage: Available in 100 - 120 V or 220 - 240 V configurations

- Material width: Supports acetate slabs from 20 mm to 50 mm

- Dimensions: 59 x 26 x 37 cm / 23.2" x 10.2" x 14.6" (W x L x H)

- Wire compatibility: OBE Flat Wire, OBE Non-Flex Hinges, OBE Standard and Premium Flex Hinges and many others flat wires and wires with hinges from manufactures worldwide.

WHAT'S INCLUDED?

- 1 pc ADVANCED SIDE SHOOTER (calibrated and ready to use)

- Exchangeable guides for different wire widths and hinges

- Power cable (US, UK, or EU plug)

- User manual in English language

Enhance your production workflow with the ADVANCED SIDE SHOOTER, delivering unmatched versatility and precision for acetate frame wire insertion. Ideal for professional frame makers who require a high degree of customization and ease in their production process.