At SMALL BATCH TOOLS, we understand that successful eyewear production is a balance of precision, efficiency, and creativity. Our solutions are designed to support you from concept to final product, ensuring every stage of your process is optimised for quality and performance.

SBT WORKFLOW

We recognise the importance of ergonomics and efficiency in both design and production. Our workflow system is structured to guide you seamlessly through each stage—whether you are drafting in Autodesk Fusion or preparing for production. Designed to keep your process streamlined and under control, it empowers you to master your craft with confidence at every step.

TAILORED SOLUTIONS FOR EVERY STAGE

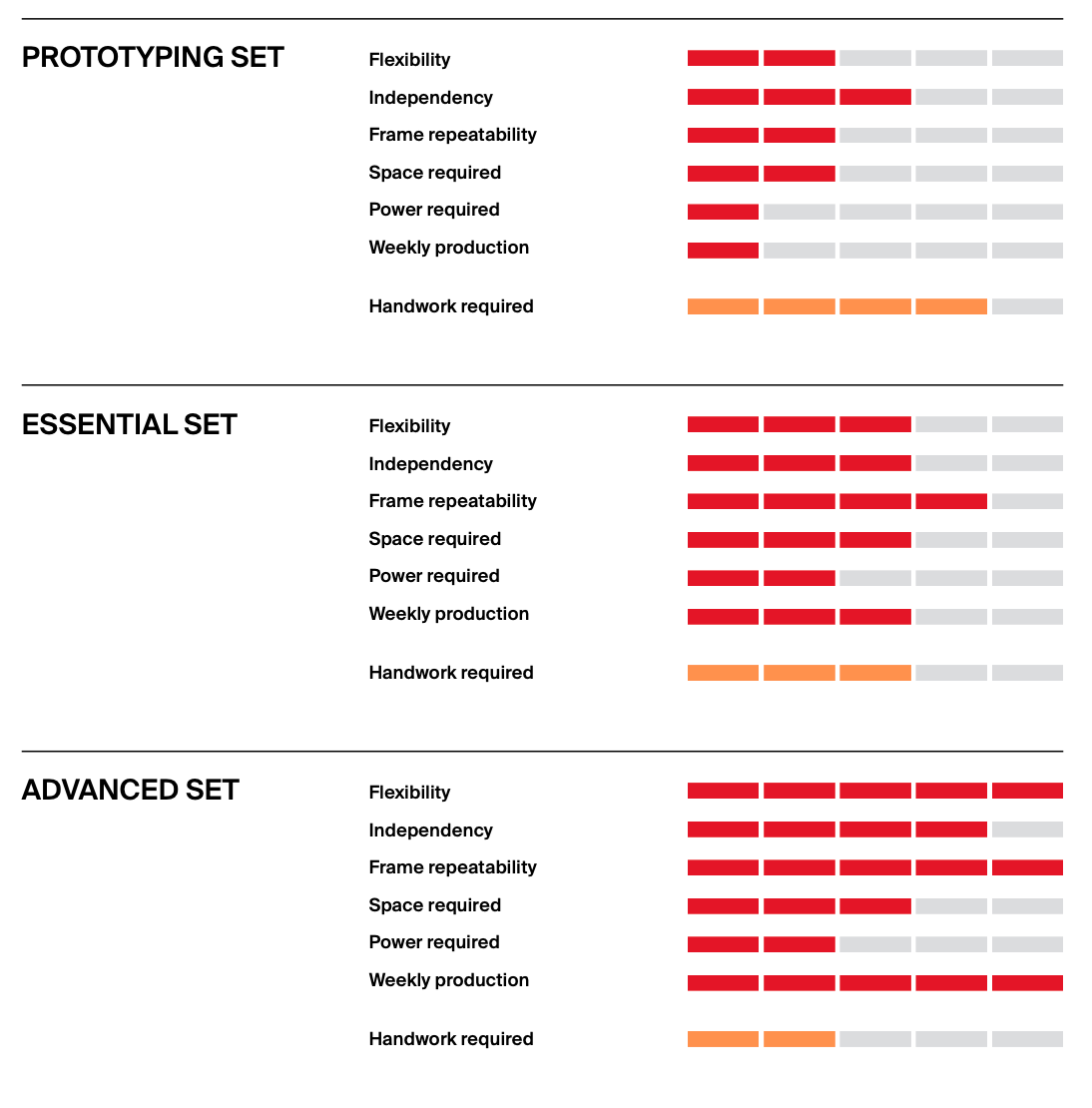

To meet the diverse needs of frame makers, we offer three distinct production solutions, each created to elevate in-house eyewear manufacturing. Drawing from the insights and successes of global makers, these solutions deliver the flexibility, precision, and efficiency needed to excel.

At the heart of every package is the EYEWEAR CNC machine—the foundation of modern frame crafting and detailed design. As you progress to more advanced solutions, you gain access to additional features that expand production capacity, refine workflow, and ensure consistent, high-quality results.

EXPLORE OUR SOLUTIONS

-

PROTOTYPING SET – A focused selection of equipment designed to launch in-house prototyping and eyewear front production.

-

ESSENTIAL SET – Purpose-built tools for emerging frame makers refining their craft, with an emphasis on bespoke eyewear and in-house brand development.

-

ADVANCED SET – A complete setup for professionals seeking maximum production flexibility, ideal for both efficient small-batch manufacturing and advanced individual frame making.

Explore the subcategories to find the solution that best suits your needs—and unlock the full potential of your eyewear production with SMALL BATCH TOOLS.