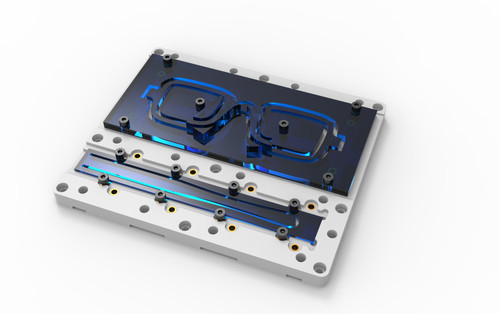

Introducing the EYEWEAR CNC

A CNC machine is an essential tool for independent and efficient eyewear manufacturing. The EYEWEAR CNC is a powerful yet affordable machine designed for high-precision milling. Equipped with HG15 linear guide rails and NEMA 17 stepper motors, it delivers excellent speed, accuracy, and reliability.

SBT 2.0 Design

- Improved performance

- Brushless spindle for precision milling

- Faster, silent stepper controllers

- Enhanced connectivity and safety features

About the EYEWEAR CNC

This machine provides professional-quality milling while remaining easy to use and control. It enables you to create high-quality eyewear without compromise. The combination of a 500W brushless spindle and a solid, compact frame ensures outstanding results.

At SMALL BATCH TOOLS, we specialise in compact CNC cutting machines and complete solutions tailored for eyewear production. Designed for high-precision manufacturing of cellulose acetate, our machines offer exceptional efficiency and reliability.

Features

- Cuts a complete frame, including temples, in 8-15 minutes

- Durable aluminum frame

- Advanced digital stepper drivers for high torque and precision

- USB motion controller for real-time, accurate processing

- Compact and efficient design

Technical Specifications

- Work size: 190 x 160 x 50 mm (X x Y x Z)

- Spindle: 500W air-cooled brushless (12,000 RPM)

- Control board: GRBL

- Linear guide rails: HG15

- Stepper motors: NEMA 23 (1.26 Nm)

- Screw type: T8x4

- Maximum feed rate: 1,000 mm/min

- Precision: 0.05 mm

- Power input: 100-240V

Dimensions

- Machine: 41 x 41 x 39 cm (16.1" x 16.1" x 15.3")

- Power box: 12 x 37 x 31.5 cm (4.7" x 14.6" x 12.4")

What’s Included?

- EYEWEAR CNC (ready to use)

- External power box

- Protective perspex cover

SMALL BATCH TOOLS Bonus

- 3x 1/8" single flute milling tools (for frame cutting)

- 3x 2mm single flute milling tools (for temple cutting)

- 10x 0.1mm engraving tools (10° single flute)

- 2x 1/8" collets (3.14 mm)

- 1x power cable (US, UK, or EU plug)

- 1x USB cable for PC connection

- Set of spanners

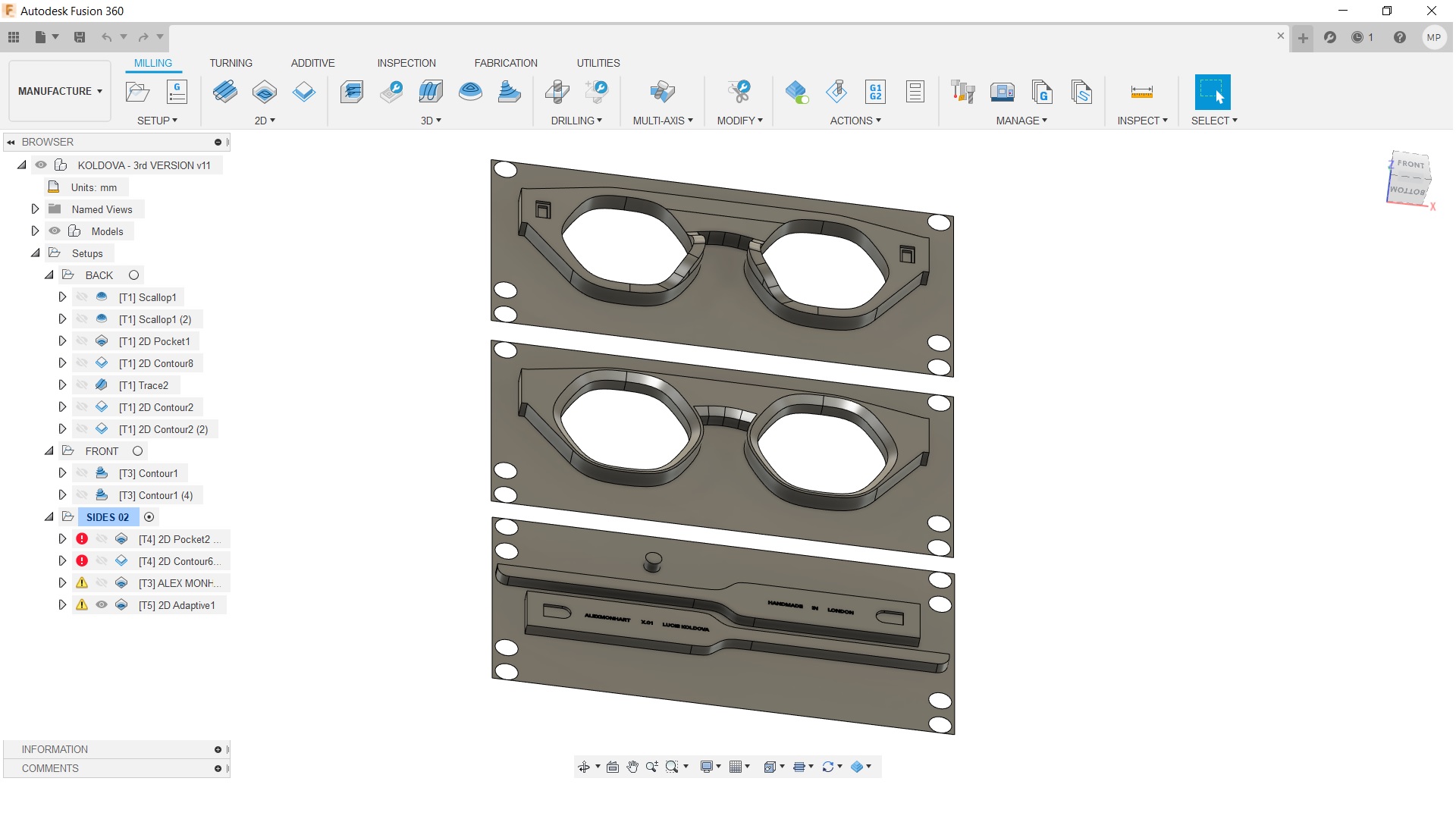

Autodesk Fusion with SMALL BATCH TOOLS

To help you get started, you can find a series of videos on eyewear frame design using Autodesk Fusion on our YouTube Channel. These include step-by-step tutorials, expert tips, and more, so you can quickly turn hand-drawn designs into real acetate frames.