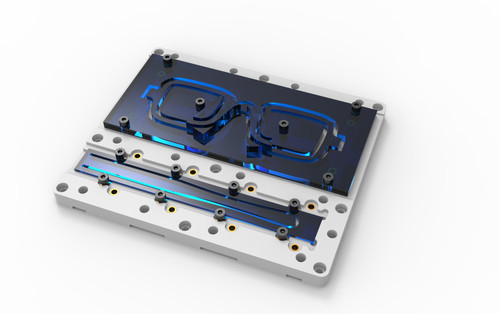

We aim to offer a convenient portfolio to cover all your eyewear manufacturing needs at SMALL BATCH TOOLS. ADVANCED CNC is our best performing CNC machine. We worked hard to bring you such a joyful and affordable CNC machine with impressive milling performance. It is equipped with 800 W spindle, high helix lead-screws, HG15 linear guide rails and NEMA 23 steppers with silent yet powerful drivers. This CNC is faster, more accurate & more powerful than all CNCs of its size.

SBT 2.0 DESIGN: Improved interface for better UX, custom made spindle mount, stronger lead screws and powerful stepper motors to boost the performance, better connectivity, new safety elements and more.

ABOUT THE ADVANCED CNC

The main difference between our ESSENTIAL CNC and the ADVANCED CNC is that this CNC has a larger spindle motor with double the RPM and larger stepper motors to handle more demanding milling in a significantly shorter period of time.

We have developed a combo of CNC cutting machines for frame makers at SMALL BATCH TOOLS. They are both designed and engineered for high precision cutting of cellulose acetate or buffalo horn with great efficiency.

FEATURES

- High quality aluminium slot profiles construction

- Custom made high helix lead-screws

- Advanced digital stepper drivers achieve a greater locking torque and positioning accuracy

- High-performance USB motion controller guarantees the transmission of the process instructions are real-time and accurate

- Fitted with custom CNC BED

- Compact design

- Anodised surfaces

TECHNICAL SPECS

- Work size: 190 x 160 x 50 mm (X x Y x Z)

- 800 W air-cooled spindle with variable frequency drive (24 000 RPM)

- GRBL firmware

- HG15 linear guide rails

- Stepper motors NEMA 23 (1.26 Nm)

- Lead screws T10x6 (X & Y axis) and T10x4 (Z axis)

- Recommended maximum feed rate: 1 800 mm/min

- Precision: 0.05 mm

- Available in 100 - 120 V or 220 - 240 V configuration

- DIMENSIONS: 42 x 41 x 40 cm / 16.5" x 16.1" x 15.7" (W x L x H)

- POWER BOX: 21 x 29.5 x 44 cm / 8.3 x 11.6 x 17.3 in (W x L x H)

WHAT IS INCLUDED?

- 1 pc ADVANCED CNC ready to use

- Including our unique CNC BED with an easy-to-use a clamping set

- External power box

- Resistant perspex cover

- SBT BONUS:

- 1 pc DRILLER tool

- 3 pcs milling tool 1/8 single flute (for cutting the fronts)

- 3 pcs milling tool 2 mm single flute (for cutting the sides)

- 10 pcs engraving tool 0.1 mm 10° single flute

- 2 pcs collet 1/8 (3.14 mm)

- 1 pc power cable (US, UK or EU plug)

- 1 pc USB cable for PC, Mac or tablet connection

- Set of ER11 spanners

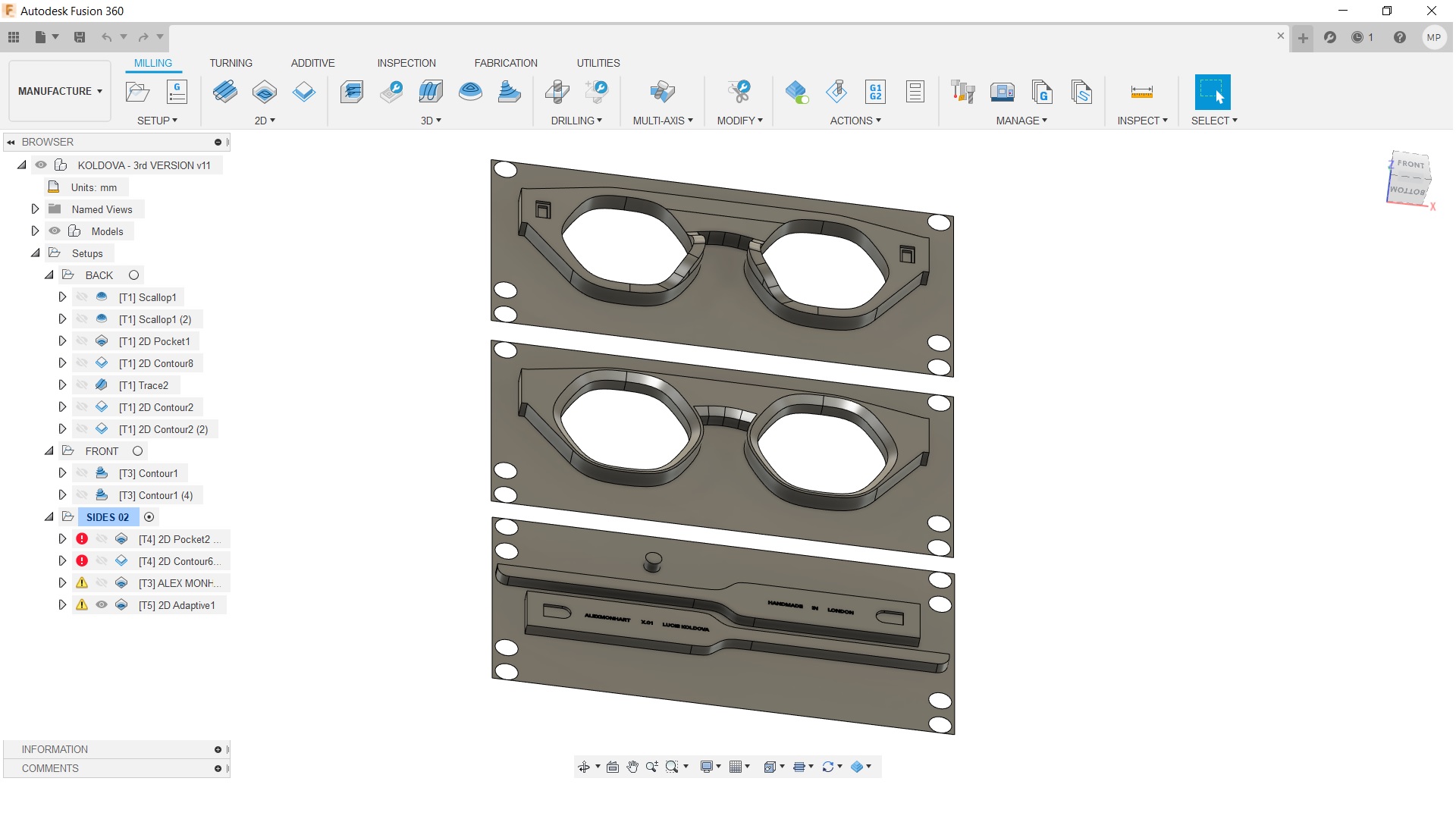

LEARN WITH SBT

We put together a practical guide book for you to assist you with the beginnings of eyewear manufacturing. It describes how to design eyewear frames in AUTODESK FUSION 360. It also has many tricks and tips on how to start from scratch and how to convert your own hand drawn designs to real acetate frames in no time. We include several already prepared designs in FUSION 360 with every purchase including all the steps for our CNC machines.